Challenges in machine vision

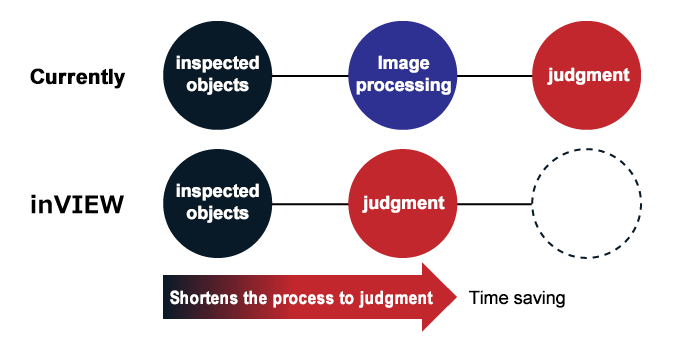

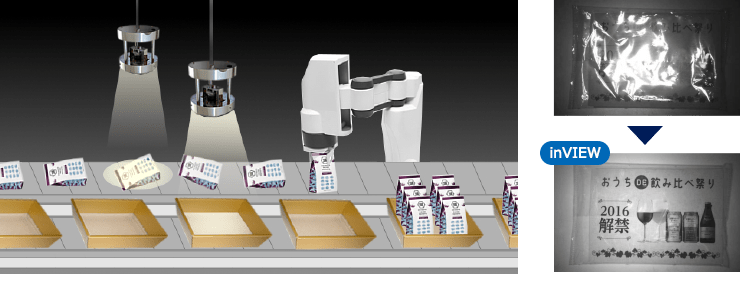

Visual inspection is commonly performed on images taken from the factory line. Scratches and foreign matter are then visualized by applying computer image processing to the captured images.

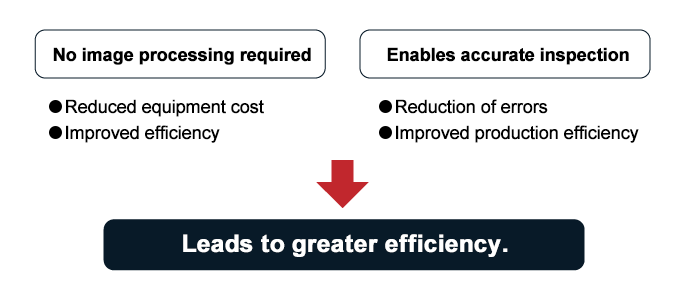

inVIEW eliminates the need for computer image processing for glare removal.

Since image judgment can be performed directly from raw images, inVIEW also contributes to time savings and reduced data volume.

With inView, there is no need for image processing!

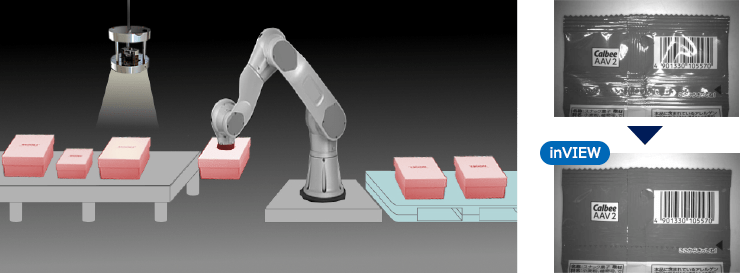

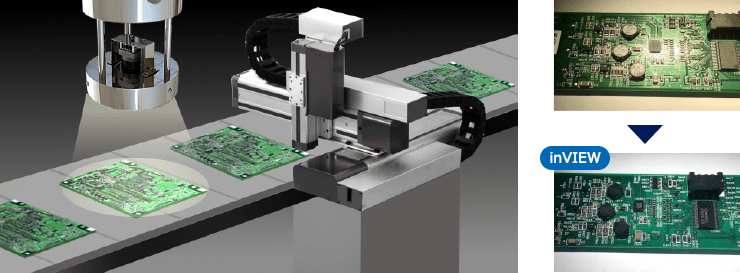

Application examples

For automatic inspection of products

For reading at random orientations

While a standard polarizing filter requires a constant orientation to clearly view the object, inVIEW can view objects at any orientation.

Reading sorting barcodes and QR codes

For reading labels and sorting equipment at logistics sites, etc.