Challenges in visual inspection

The following problems occur when inspecting precision equipment under fluorescent and LED lighting:

- Inspection quality depends on the experience level of skilled staff.

- Depending on the positioning of the production line, the lighting might not always be properly aligned.

- Eye strain can be caused by prolonged visual inspection.

Solved with inVIEW

inVIEW addresses these problems

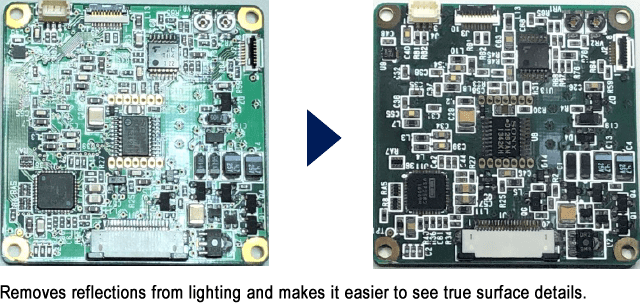

Even beginners can easily find scratches and foreign matter!

inVIEW illumination makes scratches and foreign matter stand out!

The reduced blue light illumination is gentle on the eyes.

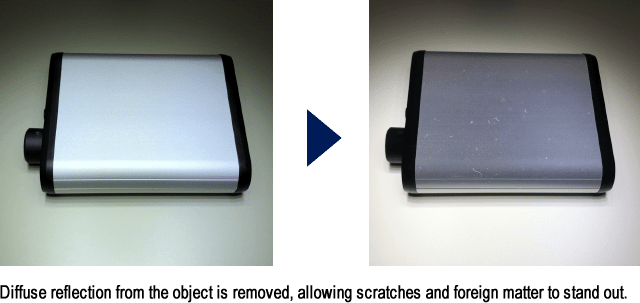

Reflective tabletop inVIEW

The reflective tabletop inVIEW is suitable for visual surface inspection tasks such as detecting scratches and dirt.

Dust and scratches can be easily detected, leading to improved work efficiency.

inVIEW illuminates objects with a special LED light source, so there is no need to worry about the orientation of the illumination. Inspection work can be performed without regards to body posture.

Multipurpose reflective illuminator for general visual inspection inVIEW WING

Multipurpose reflective illuminator for general visual inspection inVIEW WING An inspection illumination system with magnifying glass inVIEW CIRCLE LIGHT

An inspection illumination system with magnifying glass inVIEW CIRCLE LIGHT

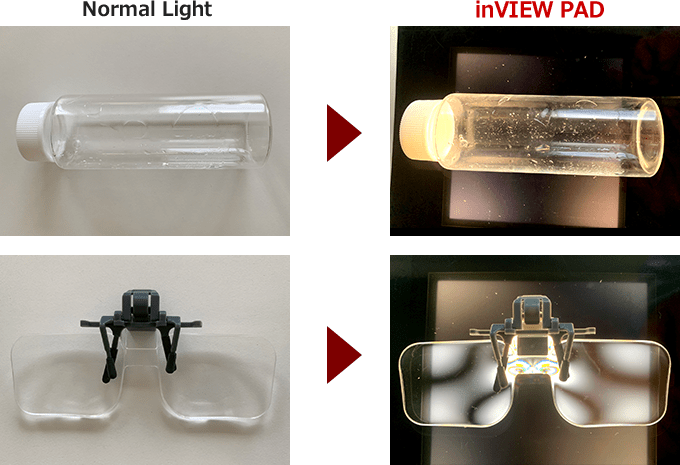

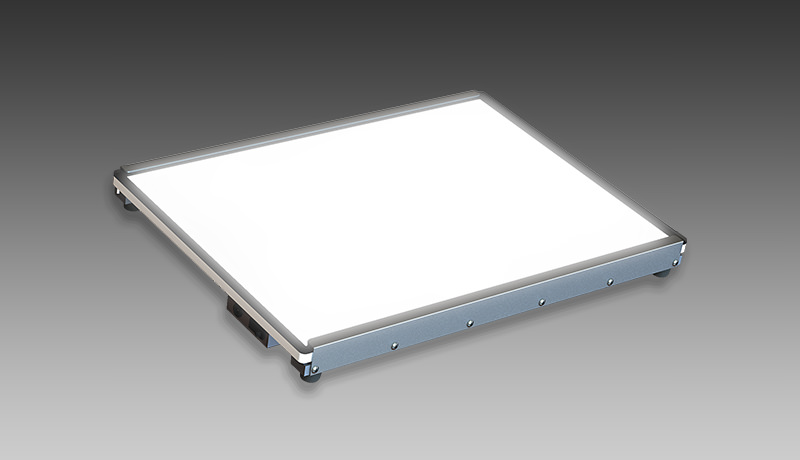

Transmissive inVIEW PAD

Lens strain and distortion, resin scratches, and foreign matter contamination that are not visible under normal lighting can be seen with inVIEW PAD.

Visual inspection transmissive pad illuminator inVIEW PAD

Visual inspection transmissive pad illuminator inVIEW PAD Transmissive type multi-type lighting system inVIEW PAD PLUS

Transmissive type multi-type lighting system inVIEW PAD PLUS