PHASERAY development story

Synqroa, Ltd. was established in 2011, the year of the Great East Japan Earthquake.

Starting with medical lighting technology, we heard from surgeons:

“Our eyes become tired from the bright light reflecting from the surgical region”

We were asked: “Can’t we eliminate the halation effect from light being reflected from the surgical area?”

Under the160,000 LUX of lighting found in surgical environments,

the intensity of the surgical light is as dazzling as sunlight.

When surgery is performed in such a bright environment for a long time,

the reflected light entering the eye causes serious eyestrain.

In response to this challenge, our Director and Technology Developer, Mr. Koyama responded,

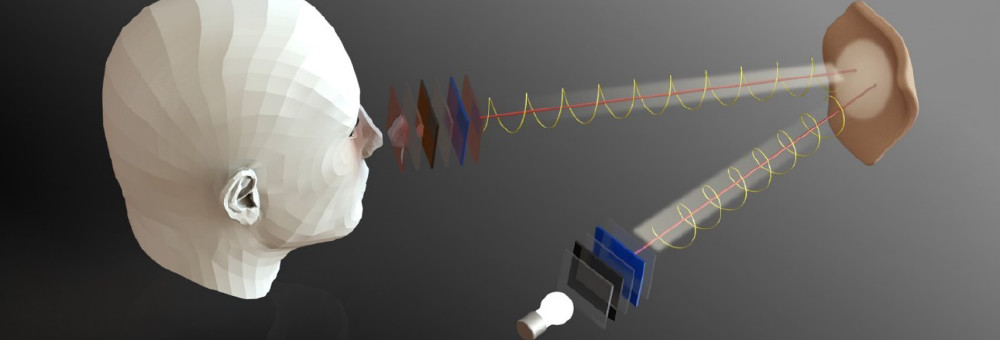

“I decided to develop a polarization technology that eliminates reflections and makes objects look realistic”.

From this idea concept, it took us about 5 years to fully develop the basic technology.

That’s how PHASERAY Technology was born.

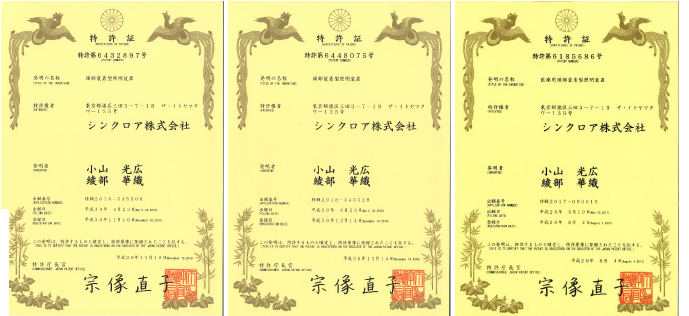

In 2018, we obtained three patents.

A new marketing initiative was commenced to decide how this technology can be applied.

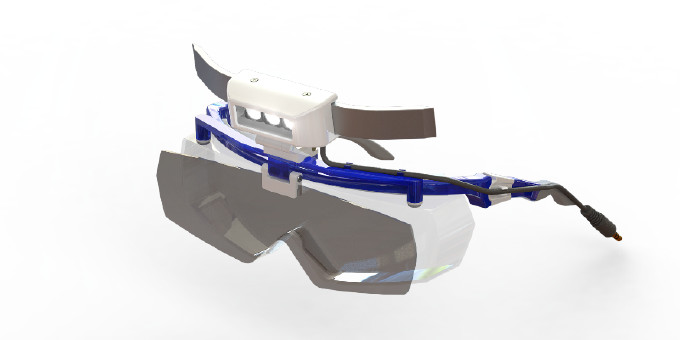

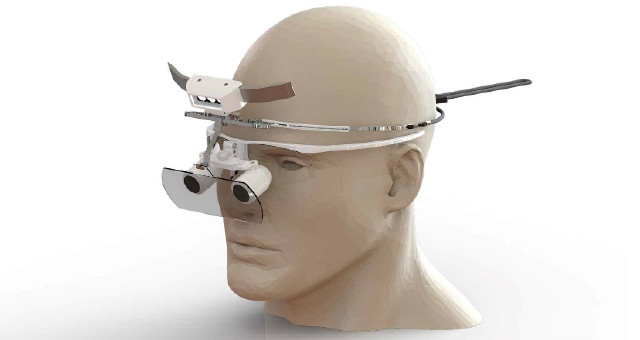

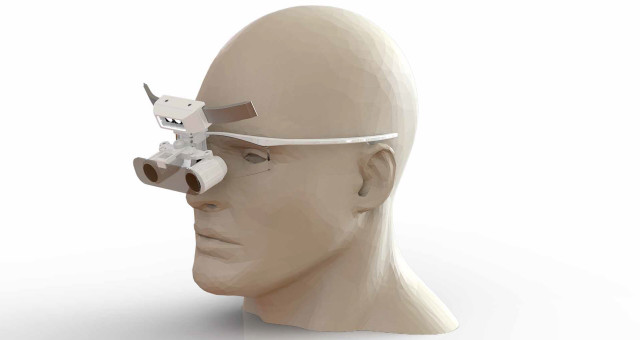

At that time, there was a lot of interest in wearable technologies.

PHASERAY technology was integrated into glasses and wearable goggles to replace loupe-type devices.

However, when glasses or goggles are worn that covers the entire face, almost all doctors feel that the device has a heavy feeling.

Also the LEDs attached to loupe-type devices can become hot.

From these results, we changed our direction, saying, “Let’s use this technology for industrial applications.”

Since 2019, we have been developing the PHASERAY technology for use as a visual inspection tool for different industrial applications. We found that the industrial inspection field did not have access to such controlled illumination and as such, we believe can greatly benefit from our PHASERAY technology.

When the shadowless technology from the medical lighting was installed in industrial visual inspection environment,

1.Details that were previously difficult to judge as simply shadows or true foreign matter can be clearly distinguished when using PHASERAY technology.

2.With our heat dissipation technology, PHASERAY products can be used for inspecting heat-sensitive objects.

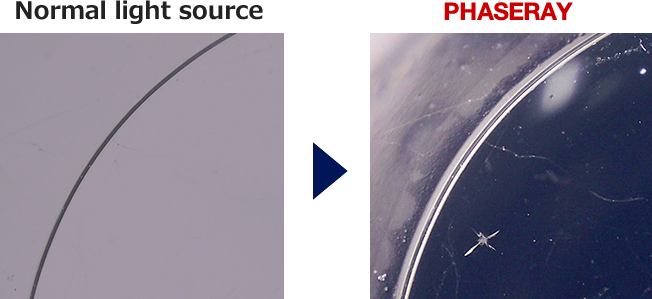

3.PHASERAY filter technology can eliminate illumination artifacts and make scratches and foreign matter stand out.

The results became clear.

Contact lens scratches can be seen.

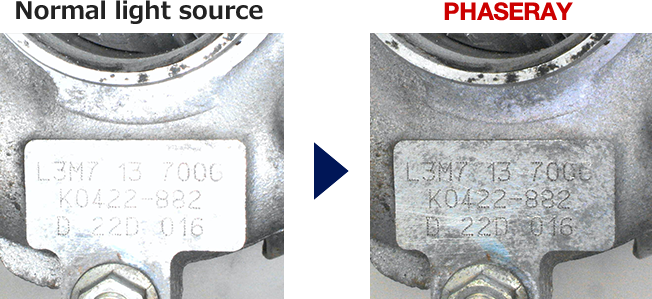

Contact lens scratches can be seen. Halation of engine parts is suppressed,

Halation of engine parts is suppressed,and surface details are clearly visible.

Nowadays, lighting using PHASERAY Technology

is widely used in industry, especially in the automotive industry.

PHASERAY Technology is a technology that can help you with any visual inspection challenge.

Our mission is to continue developing PHASERAY technology to meet various inspection challenges.